There will be different in different parts of the world but most common is to use the DNV pipeline standards DNVGL-ST-F101 Submarine Pipeline Systems as the governing standard but. Our launchers and receivers can be designed to accommodate scraper pigs sphere pigs or smart pigs or any combination of the three.

Cross Country Infrastructure Services

APC offers complete Pig Launching and Receiving Systems to meet the pipeline operators pigging needs.

. The maximum operating pressure could be 740 psi. REQUIREMENTS FOR PIG LAUNCHER AND RECEIVER DESIGN NP-1 ESUP MICROSOFT WORD V2010 I-ET-301000-1200-295-P4X-001_0 I N D E X O F R E V I S I O N S. ENGINEERING DESIGN PROCUREMENT AND CONSTRUCTION OF 10 INCH 122KM OIL PIPELINE FROM SINENDET PS26 TO KISUMU PS28 TOGETHER WITH TIE - IN FACILITIES AT PS28 FOR THE FUTURE KISUMU-BUSIA PIPELINE Data Sheet for Pig Launcher and Receiver Contract No.

Multiple Launcher Built-in Forklift Holes Removal Pins for Narrow Applications Heavy-duty Skid Base for Handling and Shipping Long Barrel Design for Smart Pig or Multi-Pig Operation Pig Receiver - Typical Features Features Patented Balance and Cleaning Gate Valve Configuration Patent Nos. Pig launchers receivers are equipped with quick opening closures as per ANSI codes. Launchers and Receivers can have many options.

This Specification defines the minimum requirements for the design materials manufacture testing and. Inspection for pipeline pig launchers and receivers pig traps in stabilised non-sour crude oil service for. The reducer should be eccentric for launcher and be concentric for receiver.

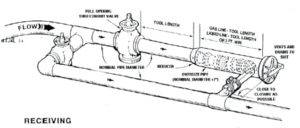

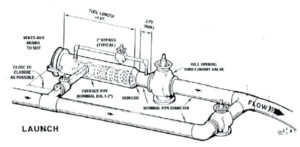

BASIC DESIGN CONSTRUCTION AND RATING 51 General 511 The following description is intended to indicate the general and minimum requirement of pig launching and receiving traps and does not relieve the supplier of his full responsibility for design fabrication performance and safety of the equipment. Pig Launching Receiving Procedures Pig launchers are used to launch the pig into the pipeline and pig receivers are used to receive the pigs after they have made a successful run. Is to be correctly assigned to each of the lines.

Pig launchers and receivers available in customer-specified colors. 100 inspected and tested. 2 Size A typical designation for pig launchersreceivers would be.

Standard design to assist clients with pig handling pig insertion into launcher or receiver and loading or removal of pipeline pigs Manufactured from durable high strength aluminum for a tool that works as hard as you do Limited flexibility of our Pigging Poles ensures hitting the target every time Drilled with. Design requirements for hydrogen pipelines are still evolving. Sloped sphere launcher Sphere signaller Vent Bypass Sphere release pins Sloped sphere receiver Drain.

Pig signaller will be in the piping design pig launcher or ASME design standards All launchers and receivers have quick opening closures for inserting removing pigs. The pig launcher and receiver or trap is designed according to subsea codes and standards given by the operator. 10-inch by 12-inch 300 pig launcher or pig launch system.

This would indicate a launcher for a 10-inch pipeline with a 12-inch oversize barrel that allows the operator to slide the pig into launch position. Made for pipelines from 6 inches through 42 inches. Mento conventional pig launchers and receivers are designed to meet the pigging requirements of pipeline owners and operators worldwide.

FES Subsea Pig Launchers Receivers Pressure range to suit client application Designed in accordance with international codes of practice including PED requirements and CE marking Design codes include PD5500 ASME VIII B313 and B318 Suitable for deep water applications depths up to 2000m. Pig signaller will be in the piping design pig launcher or ASME design standards All launchers and receivers have quick opening closures for inserting removing pigs. One of the Scraper Launchers and Receivers composed of a.

Welcome To Syschem Controls. These system packages include the Launcher Receiver Closure Pig Signal. Typical instrumentation on the pig launcher would be pressure gauges and transmitters and pig indicators to know if the pig has been launched or arrived in the case of pig receivers.

13 The physical limits of this specification are shown on. A Receiver is located at the downstream end of the pipeline to remove the Pig from the pipeline. The launchers and receivers with dimensions of 24 x 30 x 138 long and 10 x 14 x 132 long are designed for 740 PSIG at 170 degrees.

There will be different in different parts of the world but most common is to use the DNV pipeline standards DNVGL-ST-F101 Submarine Pipeline Systems as the governing standard but the code break could require ASME. Launcher Pig Receiver and Pig LauncherReceiver in PETROBRAS units. The choice of these pig traps will depend on the type of pig to be run and pipeline design conditions.

Line number material class size etc. For connection between Launcher Receiver and pipe refer to pigging operation flow diagram. Of SheetKPCSK-E-MA-DS-0001 In Replacement of 9.

SYSCHEM CONTROLS Products offers a range of standard and custom designed engineered products for all fluid handling industriesThe range of products includes Basket Strainers Bag Cartridge Filters Pig Launchers and Receivers ASME code vessels and many associated process productsIn addition to the range of our manufactured. A Launcher is located at the upstream end of the pipeline to launch the Pig into the pipeline. ANSI Class ratings between ANSI 150 and ANSI 600.

Bypass or Kick out line connection is provided along with all. Subsea Pig Launcher Design Standards. And inline inspection ILI pig launchers send pigs spheres and ILI tools into the pipeline where upstream pressure pushes them through to a receiver.

Pig Launcher Receiver shall be horizontal and the diameter of pig valves shall be equal to the inner diameter of the pipe cleaned. Different lines connected to the pig launcher are the next to be drawn up. Figure 5 Figure 6 and.

The standard receiver is provided with pig indicators. Permanent supports shall be used to support and restrain the pig traps and these shall be designed to carry the weight of the pig trap system. Design Codes Our pig traps are usually designed in accordance with.

Provisions in the station design should include handling. 740 PSIG Scraper Launchers and Receivers for a Plant in Mexico. Of trapped fluid could exceed the design pressure.

Pig signaller will be in the piping design pig launcher or ASME design standards cairnram on 01 Dec 2016 - 0642 AM said. The design of the Launcher and Receiver will depend on the Pig and pipeline design conditions. On top of.

Pig Handling System On major line diameters where the weight of the pig makes handling difficult some mechanical devices can. Pig inlet outlet and oil air or water inlet shall be connected respectively to the main pipe by valves.

Subsea Pipeline Engineering Pig Trap Pig Launcher Intelligent Pig

General Overview Launchers And Receivers Sure Flow Equipment Inc

Cross Country Infrastructure Services

Pig Launchers Receivers Products Swecofab

0 comments

Post a Comment